專業技術支援.卓越優良品質.即時快速反應

Service Oriented, Sprint of Response, Support of Technology, Superior Quality

探索我們的產品 Explore Products致力於研發、生產 LCD 光電產業及半導體製程所使用之光阻材料。

Dedicates to innovating and supplying photo-resistors of LCD for the semi-conductor industry.

鎧暘科技成立於 2003 年,為全球少數擁有 LCD 上游關鍵性製程所需光阻材料研發及量產實績之公司。我們秉持「客戶服務導向」的精神,為次世代產品開發提供最強力的後盾。

TopGiga Material Corporation was founded in Oct. 2003. It is one of a few leading companies which can provide total solutions for innovative photoresist materials used in the LCD industry.

西元二○○三年十月,鎧暘科技(TopGiga Material Corp.) 正式成立!致力於研發、生產LCD光電產業及半導體製程所使用之光阻。鎧暘為全世界少數可以擁有LCD上游關鍵性製程所需使用之BM、RGB、 Overcoat、 MVA、Photo Spacer、Array PR等光阻材料研發及量產實績之公司,部分光阻材料之技術更已取得世界領先的地位。

客戶服務導向、專業技術支援、卓越優良品質、即時快速反應是我們的核心價值。

TopGiga Material Corporation was founded in Oct. 2003. The company dedicates to innovating and supplying photo-resistors of LCD for the semi-conductor industry.

It is one of a few leading companies which can provide total solutions for innovative photoresist materials used in the LCD industry and for mass productions.

Meanwhile, we have invented some leading-edge LCD material products in the world.

TopGiga’s business philosophy is 4S: Service Oriented, Sprint of Response, Support of Technology, and Superior Quality.

.png)

.png)

鎧暘科技的核心競爭力在於:技術掌握能力強、交期短、包裝安全簡便、價格合理。

Service Oriented / Sprint of Response / Support of Technology / Superior Quality

Joint Research for all applications photo resistors.

TopGiga’s Core Values: Develop most suitable materials, Adjust to the varying market, Help reduce inventory levels, Reasonable prices.

鎧暘科技盡一切努力提供優良產品及服務以滿足客戶之期望,並期許成為客戶長期互惠的夥伴及可靠之供應商。

鎧暘科技秉持積極、主動的精神發掘並解決問題,並堅持專業、細心的態度提供零缺點的產品。

鎧暘科技承諾充分運用人力、技術、設備等資源,持續提供客戶最好的產品、以客戶滿意為優先、品質第一為信念,貫徹執行品質政策。

TopGiga will do its best to provide excellent product and service to fulfill customers’ expectation, which lead to be the most reliable supplier in the market.

TopGiga will dissolve any problems progressively and actively to provide zero-defect product with professions and cares.

Customers’ satisfactions and quality are our first priority to quality policy.

TopGiga accomplished ISO 9001 certification in 2005, ISO 14001 certification and ISO 45001 certification in 2012.

大世代 PS 導入台灣前兩大面板廠之一的 TV 供應鏈

Array 正型光阻導入台灣前兩大面板廠之一,並同步實現環保綠能概念

高精細 PS 導入華南 LTPS 廠品牌手機供應鏈

RGB 光阻跟既有客戶策略合作,協助整合收斂規格

大世代 BM 在既有的兩大 TV 面板客戶,推進實績

OC 光阻導入台灣前兩大面板廠 G5~G6 等數個廠區

OC 光阻導入台灣另一個前兩大面板廠的 CF 廠供應鏈

With the technical advantages, TG’s PS product enters the mass production stage in two G8.5 and one G4.5 plants of the top China FPD corporate.

Introduction of OC photoresist product into two major Taiwanese FPD makers.

Introduction of advanced PS photoresist product into the supply chain of mid-China FPD makers.

Introduction of more than two CF negative-tone photoresist products in two new FPD plants in China.

OC photoresist introduced into the G6 factory of the largest panel group in China.

Introduction of RGB photoresist products into the supply chain of China G6 LTPS FPD makers.

Introduction of BM photoresist product into another China G8.5 FPD maker.

Provide G4.5 FPD maker in mid China with full range material solutions.

TG introduces PS photoresist product into one of the G6 plants of the top FPD corporate in China.

The First Product of Photo-Spacer Adopted by a COA Technique Equipped Generation 8.5 LCD TV Maker in Mainland China.

The First Product of Positive-tone Photoresist for the Application of Wafer Bumping Adopted by the Korean Semiconductor Supply Chain.

Total Solution of Materials and Services Offered to Generation 6 Hi-End LCD Maker.

The Product of Special Purpose-Oriented MVA Photoresist Adopted by a Generation 6 LCD Maker.

The First Product of Resin Black-Matrix Adopted by a Generation 8.5 LCD TV Maker.

Nikon-Oriented Photo-Spacer Adopted by two LTPS Medium to Small LCD Makers in Mainland China.

Received certification for ISO 14001 and OHSAS 18001.

TopGiga Material Corp. Opens Doors to new headquarter in Zhunan.

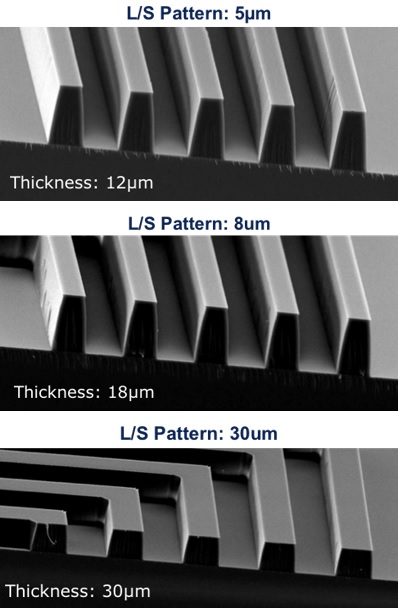

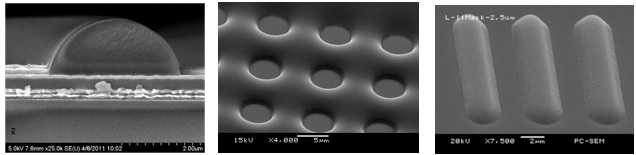

適用於線路重分布製程 (RDLs),可使用於銅/金/鎳等多種電鍍液定義線路圖形。

Applied in Redistribution Layer (RDL) processes with various plating solutions (Cu/Au/Ni) to define circuit patterns.

適用於封裝技術的高膜厚電鍍/電鑄製程 (銅/金/鎳),定義線路圖形。

Suitable for high film thickness plating/electroforming processes (Cu/Au/Ni) in packaging technology.

適用於軟性基板電路 (FPC) 捲軸式生產,可使用於多種蝕刻液。

Applied in Flexible Printed Circuit (FPC) film production using reel-to-reel methods.

應用於高色域產品 (NTSC 達 85% 以上),使液晶螢幕呈現更鮮豔的色彩。

Wide Color Gamut products (NTSC > 85%) for richer and vivid pictures.

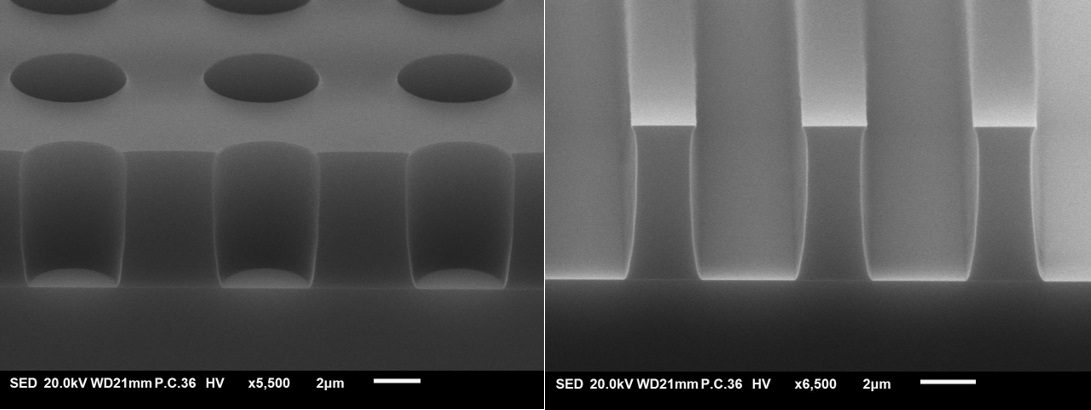

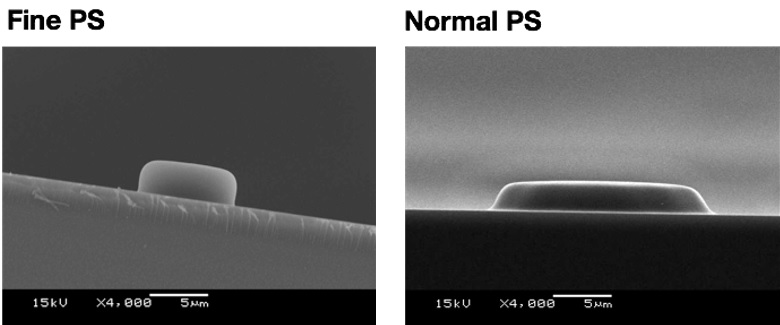

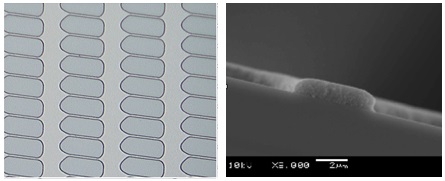

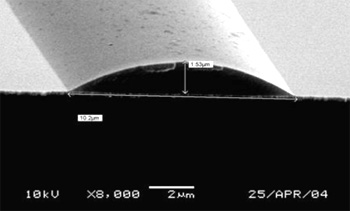

TFT-LCD Panel 結構中的關鍵間隙材料。

Key material for controlling liquid crystal thickness in TFT-LCD panels.

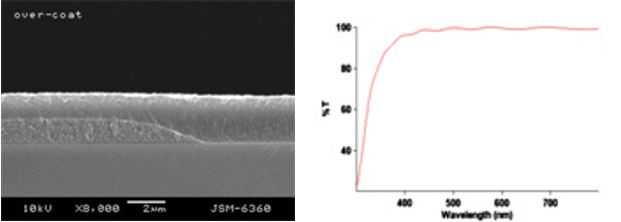

以最小厚度製作黑色矩陣,減少 RGB 斷差並降低 Overcoat 厚度。

Reduces thickness difference between RGB layers and lowers Overcoat film thickness.

多象限垂直配向技術,提升可視角 (達 170 度) 與反應時間 (25ms)。

Multi-Domain Vertical Alignment technology for wider viewing angles (170°) and fast response (25ms).

隔離液晶與防止污染,兼具黑色矩陣與透明電極層的絕緣材。

Separates BM and ITO electrode, prevents liquid crystal contamination.

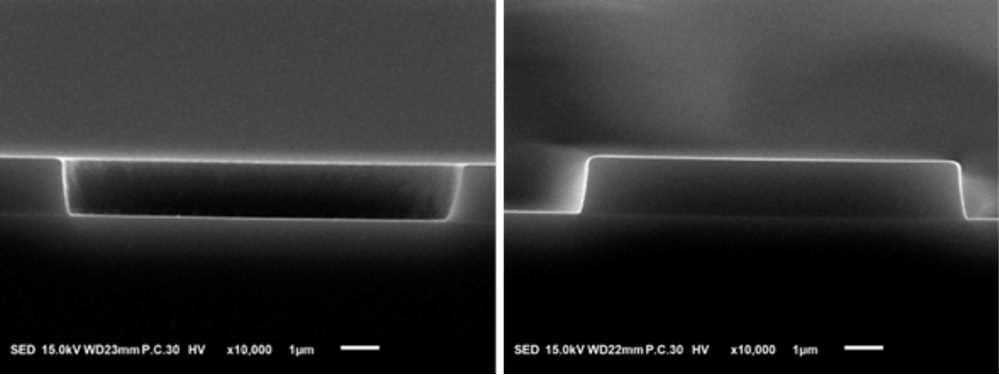

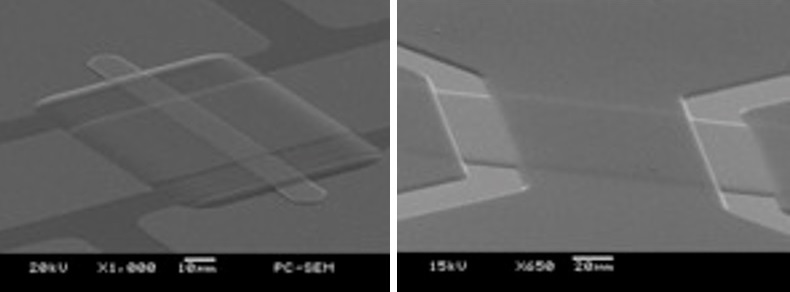

應用於 Array 端線路蝕刻保護,對應 FFS、IPS、LTPS 等高階技術。

Pattern transfer for TFT-Array designs, suitable for FFS, IPS, and LTPS technologies.

應用於觸控面板線路及 Sensor 設計的圖形轉移,提升良率及產量。

Pattern transfer for wires and sensors in Touch Panels, aiming for high yield and capacity.

相關產品資訊,請洽營業部門陳小姐。

Please contact Dolphin Chen for more information regarding Dot Spacer and Sealant products.

開放式的管理風格、講求創新及效率的企業文化!

鎧暘提供您良好的學習環境、暢通的溝通管道及豐富的生涯規畫!

員工保險:勞健保、團保、意外險、醫療險

休假制度:週休二日、婚喪假、陪產假、生理假

Please check www.104.com.tw for the latest recruiting information.

Contact Person: 037-691-800 ext.599 Ms.Tseng

Visit 104.com.tw地址:350 苗栗縣竹南鎮科研路 48 號

電話:037-691800

傳真:037-691801

Address:No.48, Keyan Rd., Zhunan Township, Miaoli County 350, Taiwan

TEL:886-37-691800

FAX:886-37-691801